PRODUCTS

K type

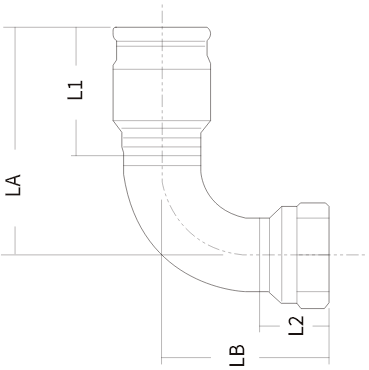

WATER TAP ELBOW

Size Information

| Order No. | Standard (su x su) | Size (mm) | ||||

|---|---|---|---|---|---|---|

| LA | LB | L1 | L2 | Tolerance | ||

| KWE 1315A | 13×1/2″ | 75 | 45 | 51 | 23 | ±3 |

| KWE 2015A | 20×1/2″ | 83 | 53 | 51 | 23 | ±3 |

| KWE 2020A | 20×3/4″ | 83 | 55 | 51 | 25 | ±3 |

| KWE 2515A | 25×1/2″ | 90 | 60 | 51 | 23 | ±3 |

| KWE 2520A | 25×3/4″ | 90 | 62 | 51 | 25 | ±3 |

| KWE 2525A | 25×1″ | 90 | 64 | 51 | 27 | ±3 |

※BSPT(internal parallel): Rp(PS)

※BSPT(internal parallel): Rp(PS)

KWE 1315A

| Standard (su x su) | |||||

|---|---|---|---|---|---|

| 13×1/2″ | |||||

| Size (mm) | |||||

| LA | LB | ||||

| 75 | 45 | ||||

| L1 | L2 | Tolerance | |||

| 51 | 23 | ±3 | |||

KWE 2015A

| Standard (su x su) | |||||

|---|---|---|---|---|---|

| 20×1/2″ | |||||

| Size (mm) | |||||

| LA | LB | ||||

| 83 | 53 | ||||

| L1 | L2 | Tolerance | |||

| 51 | 23 | ±3 | |||

KWE 2020A

| Standard (su x su) | |||||

|---|---|---|---|---|---|

| 20×3/4″ | |||||

| Size (mm) | |||||

| LA | LB | ||||

| 83 | 55 | ||||

| L1 | L2 | Tolerance | |||

| 51 | 25 | ±3 | |||

KWE 2515A

| Standard (su x su) | |||||

|---|---|---|---|---|---|

| 25×1/2″ | |||||

| Size (mm) | |||||

| LA | LB | ||||

| 90 | 62 | ||||

| L1 | L2 | Tolerance | |||

| 51 | 23 | ±3 | |||

KWE 2520A

| Standard (su x su) | |||||

|---|---|---|---|---|---|

| 25×3/4″ | |||||

| Size (mm) | |||||

| LA | LB | ||||

| 90 | 62 | ||||

| L1 | L2 | Tolerance | |||

| 51 | 25 | ±3 | |||

KWE 2525A

| Standard (su x su) | |||||

|---|---|---|---|---|---|

| 25×1″ | |||||

| Size (mm) | |||||

| LA | LB | ||||

| 90 | 64 | ||||

| L1 | L2 | Tolerance | |||

| 51 | 27 | ±3 | |||

Why

Over USD$20MM of revenue from the projects in Japan Taiwan since 2005

- Since 2005, ez joint has been used in Japan and Taiwan, which are high-risk earthquake countries. More than 4,000 projects, the cumulative exports amount exceeded USD$20MM.

- Registered for SAS 322 certification (Japan Stainless Steel Association)

- An earthquake-resistant product that absorbs internal and external shock vibrations caused by earthquakes.

Technology proven Technology proven for over 20 years of installation history

- The proprietary technology of EZ JOINT started in 2000.

- EZ JOINT’s technology has been verified at various construction sites for 22 years in Korea, Japan, Taiwan and Russia.

- We do our best to provide services to maintain customer’s trust.

Fast and easy to use

- Fast and easy to use which completes installation only by inserting a pipe after cutting the pipe.

- No tools needed. Fast and easy to use.

Easy Installation

Anyone can install it without any professional skills.

- One-touch push-fit technology, anyone can install EZ JOINT.

- No pressing tools and no electricity needed.

Cost saving

Fast and saving time. Reusable technology

- Excellent cost saving. Fast installation time saves labor costs and shortens construction schedules.

- You can not only reuse ez joint but also reuse installed pipes, if you uninstall EZ JOINT.

Easy maintenance

- Proprietary technology with over 28 patents.

- Good for the instance of construction design changes, renovations, and other A/S situations.

- If you want to redesign your plumbing projects, you can easily uninstall EZ JOINT and change the project.